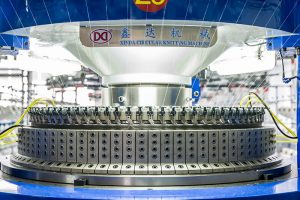

1.What is Circular Knitting Machine

The ماكينة الحياكة الدائرية also called weft circular knitting machine.

The circular knitting machine has developed rapidly, because of the following factors:

- The feeder system(Also called feeders in the factories)

- High speed

- High productivity

- Swiftly-change of the shape

- The excellent quality of the fabric

- The simple fabrication procedure

- Well-adapted of the product

2.The Categories of Circular Knitting Machine

Single knit Series:

Single Jersey Circular Knitting Machine, Single Terry & Reverse loop Circular Knitting Machine, Three Thread Fleece Knitting Machine, Open-Width Single Jersey Circular Knitting Machine

Double Knit Series:

Interlock & Rib Circular Knitting Machine, Body Size Double Jersey Circular Knitting Machine, Open-Width Double Jersey Circular Knitting Machine

Interlock & Rib Circular Knitting Machine, Body Size Double Jersey Circular Knitting Machine, Open-Width Double Jersey Circular Knitting Machine

Computerized Jacquard Series:

Single & Double Computerized Jacquard Knitting Machine, Single Computerized 4/6 Color Auto-Striper Jacquard Knitting Machine, Terry Computerized Jacquard Knitting Machine.

Single & Double Computerized Jacquard Knitting Machine, Single Computerized 4/6 Color Auto-Striper Jacquard Knitting Machine, Terry Computerized Jacquard Knitting Machine.

Latest technology: High-Speed Machine(very popular in India); Rib Transferred Jacquard Machine; Linking Jacquard Machine.

3. The Principle of Circular Knitting Machine

Single Jersey Circular Knitting Machine

With the promotion of the transmission gear, the yarn would be transferred to the textile(knitting) area by the yarn feeder. When the yarn feeder puts the thread into the needle, it will move around the camp setting area. And the following process includes the needles that permit the loops to be formed, held on the needle until a new loop is made, and then knocked off to gradually build the knit structure. The taking down motion equipment will stretch the knit structure evenly and continuously and wind it into a certain shape. When it reaches to a certain RPM, the machine will turn itself off automatically. And that’s the procedure of producing a bolt of cloth. During the whole process, there is some other equipment like the dust cleaner, the automatic oil lubricator, and the self-stop equipment to make sure the well-function of the machine and the quality of the cloth.

طلب:

T-shirt, Towels, underwear, etc.

ماكينة الحياكة الدائرية ذات الجيرسيه المزدوج

Basically the same as the single jersey machine, the main differences are:

1) There is the equipment like the dial and the cylinder for the double jersey machine.

2)The both sides of the double jersey machine can form the loop.

طلب:

Floor mats, carpets, scarves, etc.

4.Brands of Circular Knitting Machine

European Brand

Terrot– the Long-lasting giant in Europe.

Top performance in the production of electronic and mechanic controlled circular knitting machines. In 1862, Terrot started to manufacture the knitting machines. They have the plenty of experience as one of the most successful companies in the knitting machine industry. According to their clue, “experience makes the difference” Their experience provide them the expertise and to produce the good performance machine.

European Brand

Santoni—Top seamless knitting machine manufacturer

Created in 1919 Santoni is the very first Italian sock knitting machine manufacturer. Santoni has Dozens of years experience and the stabilized customer group. In the past 20 years, Santoni has developed a series of circular electronic “Seamless wear” knitting machines becoming a worldwide leader in this technology. The seamless machine, regarded as their most important product, has been considered as a revolution for the textile machine industry. Their constant drive in Research and Development and subsequent innovations also made enable them to shift easily from one sector of the textile field to another.

Japan

Fukuhara—Seen as a leading brand with the precision

![]()

Fukuhara enjoys a good reputation for its precise machine and attitude. They have a strict quality-control process. Apart from this, the Fukuhara Group has the unique business structure and the complete industry chain. They are the manufacturer of the circular knitting machine but also the manufacturer of the needles, the sinkers or other accessories. All these products are sold as the Fukuhara brand. This large scale group can provide them a large amount of capital support and the lower cost. With the technology advantage, they manufacture all kinds of the circular knitting machine.

Taiwan

Pailung—Keep going with the innovation and research

Specializes in innovation research. They built an independent open innovation lab to research and develop the new methods of the circular knitting machine. They are famous for their quality control testing to guarantee the quality of the circular knitting machine and avoid any of the flaws. Besides, they establish complete marketing channels in China and lots of countries in the world by their large amount of agents.

Chinese Mainland Sintelli — Chinese Up- rising star in the textile area

With more than 40 years experience in textile industry, Sintelli is one of the first group companies that started manufacturing the circular knitting machine. Sintelli also has been the fabric producer for its first 20 years, and with the experience in producing fabric, Sintelli knows what do the clients need more than other companies. Sintelli believes the principle of “Customer always ranks first” to enjoy a popularity over the domestic and international market. Now Sintelli has the factory that covers 100,000 square meters and achieved the ISO 9001 quality Certificate, CE, and other certificates. Sintelli owns complete and specialized technology team and after-sales service sector to solve various problems of our clients. On account of locating in China, with the welfare policy and the low-labor cost, compared to the above international brands, Sintelli brand offers the more competitive price and with the not inferior quality.

5. How to Choose Right Circular Knitting Machine

Situation: Many clients who want to purchase the machine for the first time don’t know about what the special type of the machine to choose. That is a problem the customers and Sintelli usually meet. A lot of customers don’t have much knowledge about the machine, the single jersey, the double jersey, or the jacquard series, as well as parameter: the diameter, the gauge, the feeder etc.

3 Important Parameters: the Diameter, the Gauge and the Feeder (picture)

1) The Diameter: the Diameter is the diameter of the cylinder, which also determines the size of the cloth.

2) The Gauge: the Gauge determines the density of the cloth. The less the gauge is, the lower density the cloth has.

3) The Feeder: the Feeder determines the production, higher feeder, higher production the machine has.

Generally, our clients can get the special model type from the following 3 ways:

1) To consult the people who have the knitting machine experience, and then give us the detailed information of the machine.

2) Show us the fabric picture, our technician can determine whether we can manufacture and know about the normal model type.

3) Send us the fabric sample, our staff can analyze the fabric and know what exactly do you need (including the parameter).

To make you understand this more clearly, we take our client, Mr. Tom, for instance:

Tom owns a factory to manufacture the sports cloth, at the beginning when he found us to offer him the quotation of the circular knitting machines, he doesn’t know what kind of circular knitting machine he needs, so he sent us the following fabric pictures:

We rank the fabrics by the letters. From above pictures, these fabrics can be produced by the single jersey circular knitting machine. By analysis, we offer him a professional solution for his machine purchase. The fabrics E,F,J, K can be produced by the 34” 28G 102F Single Jersey Circular Knitting Machine, and by changing the cams arrangement, this machine can also produce the mesh fabric, which is the fabric B and C. As for the fabric A and G, we only need to change the cylinder to 24G cylinder. With our solution, Mr. Li only need to buy the 34″ 28G 102F Single Jersey Circular Knitting Machine with the additional 24G cylinder, then he can produce the above 9 kinds of fabrics!

Besides, for these three kinds of fabric, our 34” 28G 72F Double Jersey Circular Knitting Machine is equal to produce.

According to the case of Tom, we can offer our clients the best solution for communicating in this way.

That’s how Sintelli does for the principle of “Customer first”, if you have any intends to buy the machines, why not start contacting with Sintelli right now?